KITCHEN(TABLE) TOPS

KITCHEN(TABLE) TOPS

Category:

Boards

This product is provided by the company NOVIN CHOOB INDUSTRIAL GROUP . Please contact for more information.

Product Description

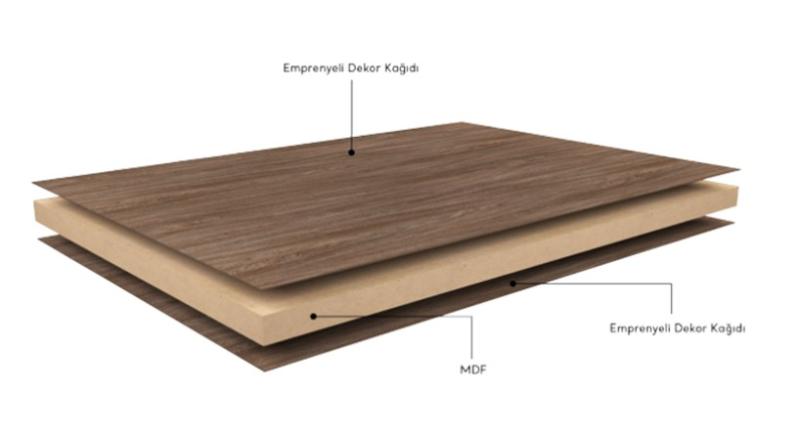

The cabinet panel produced in Novin Choob Khuzestan Industrial Group is a product that consists of a raw MDF core covered with HPL coating.

In short, MDF is the combination of wood chips and cellulose fibers, which is combined with resin glue and other required materials, and after a process with high heat and pressure, it becomes an integrated and uniform piece called raw MDF. It is produced in different thicknesses.

When we cover the raw MDF with a coating called HPL, we call the final product a cabinet plate.

HPL, which is abbreviated as High Pressure Laminate, is actually a thin sheet but with many features, which makes raw MDF covered with it, become a suitable and high-quality product for use in various applications. to be

As the name of this product suggests (high pressure laminate), it can be said that HPL is also a type of melamine, with the difference that it has higher compression and resistance than normal melamine.

The HPL sheet, which is also known as Formica, consists of several layers. Its first few layers are made of kraft paper stacked on top of each other. These layers are glued together with phenolic resin. This paper, as seen from the meaning of the word Kraft (resistance - strength), is a very resistant and durable paper. The main reason for the high strength of the HPL sheet is the use of the same kraft papers in its constituent layers.

A layer of patterned paper impregnated with melamine resin is placed on the last layer of kraft paper, and this layer creates the design and pattern of HPL paper.

As the last layer, a protective and colorless layer is placed, which makes the HPL sheet anti-scratch, anti-stain, etc. (In the following, we will discuss all the features of the HPL sheet)

All these layers are glued together under high heat and pressure and after going through a special process and form the HPL sheet.

Other Products of the Company

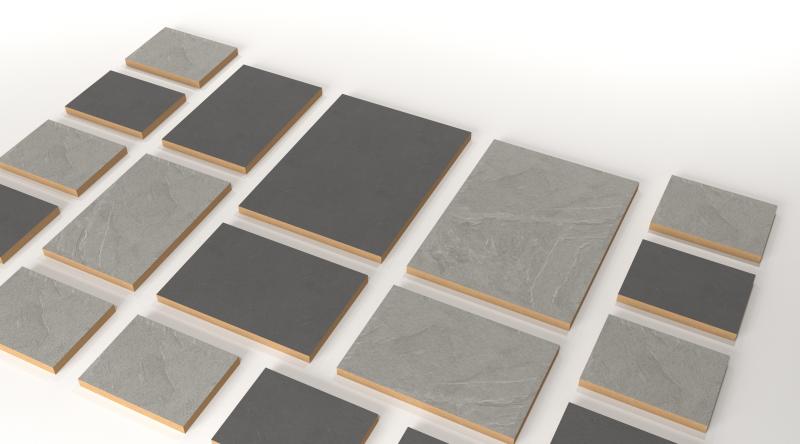

See AllMELAMINE MDF BOARDS

MELAMINE MDF BOARDS

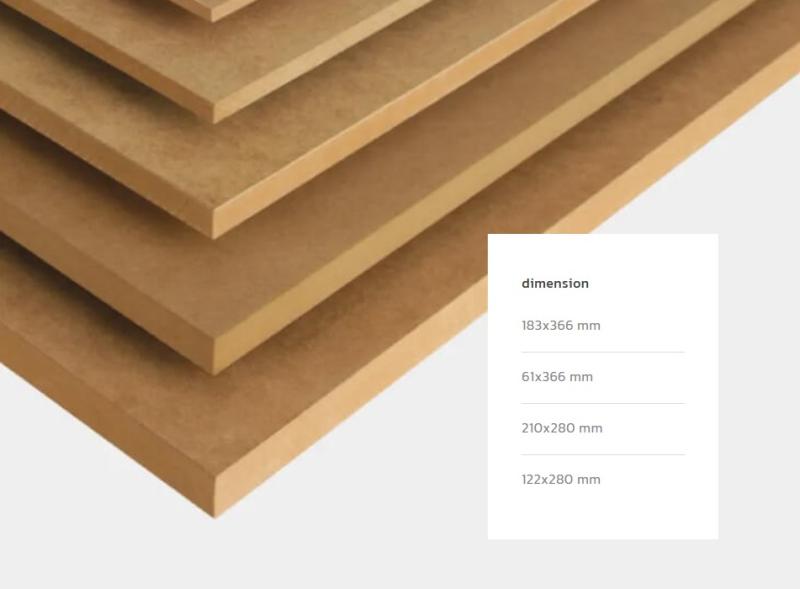

RAW MDF BOARD

RAW MDF BOARD

MDF BOARDS LAMINATED WITH HIGH GLOSS PVC FOIL

MDF BOARDS LAMINATED WITH HIGH GLOSS PVC FOIL

SYNCHRONIZED MELAMINE BOARD

SYNCHRONIZED MELAMINE BOARD

Similar Products

See AllSurface Solutions

Antiscratch Ultra Matt/High Gloss PET Rolls

Surface Solutions

Ultra Matt / High Gloss Acrylic Surface Sheets

high glossy and super matt decor panel

furniture door panel

Decoration laminated boards