| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

BOZOK MÜMESSİLLİK MAKİNA KİMYA SAN. VE TİC. A.Ş.

Caddebostan Mah. Gökçe Sok. Erenli Apt. No: 8 D: 1 / Kadıköy / İSTANBUL / TÜRKİYE

|

Contact Info: +90 216 385 9499

|

Hall: 6

Stand: 601 B

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Electronic Wood Systems is an innovative high-tech company in the field of quality control systems for the wood panel industry and in the field of spark extinguishing systems. It was founded in 1996 by Hans-PeterKleinschmidt. The company operates internationally and cooperates with worldwide partners. Head office, research & development and manufacturing are located in Hamelin (Germany), 50km [30 miles] south of Hanover.

Continuous Thickness Measurement avoids waist of raw material and energy. Production of panels which exceed plustolerances results in increase of production cost. This also results in consumption of additional (unneeded) glue and war material while also extending the press time.

Non-contact measuring of particle and fiber moisture. Multi-wavelength infrared light is used which is targeted to, and reflected by the material surface. A certain wavelength of infrared light is absorbed by water molecules, thus more or less weakened. The weakened signal is compared to the unweakened signal. The resulting values indicate the moisture content.

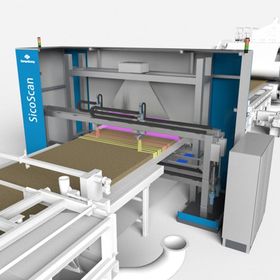

Two advantages respectively two measuring functions based on x-ray technology are combined in one EcoScan NEO system. This is a High Precision Area Weight Measurement of the fiber mat and a Foreign Body Detection . Each measuring function can be created as a separate measuring system (stand-alone)

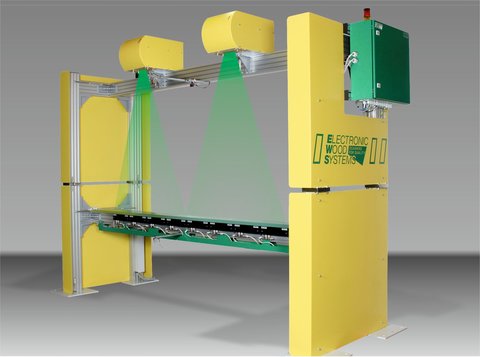

Detect blows, bursts and unglued areas during the production of wooden composite panels. They send inaudible ultrasound through the panels and can be deployed in harsh production environments, such as dust, steam and high temperatures.

Finding out the unrealized potential through the use of weight per unit area gauges. One of the most vital factors in the production of wood panels is the constant spreading of material.

An ideal density profile is essential in the production of quality wood based panels. Beside quality assurance, expensive overdimensioning can be avoided. The laboratory density profile measuring system DENSE-LAB X determines the density distribution over the sample thickness (perpendicular to the panel surface) on small samples with the usual dimension of 50 x 50 mm². The measurement is non-destructive and non-contact using X-ray technology.

Two advantages respectively two measuring functions based on x-ray technology are combined in one EcoScan NEO system. This is a High Precision Area Weight Measurement of the fiber mat and a Foreign Body Detection . Each measuring function can be created as a separate measuring system (stand-alone).

Continuous non-contact Panel Scale, determins the panel weight and its distribution during production by measuring the area-weight and by taking the known panel dimensions into account.

The company has no registered brand information.

TR

TR